Alloy Steel Base (Adamite) Rolls

Top Alloy Steel Base (Adamite) Rolls Manufacturers – Vimco Rolls Pvt Ltd .

Vimco Rolls Pvt Ltd is proud to be among the top Alloy Steel Base (Adamite) Rolls manufacturers, offering precision-engineered rolls that deliver exceptional strength, wear resistance, and consistent performance for various rolling mill applications.

Alloy Steel Base Rolls, commonly known as Adamite Rolls, are hyper-eutectoid steel rolls with a high carbon content ranging from 1.0% to 2.0%. These rolls are alloyed with essential elements like Nickel (Ni), Chromium (Cr), and Molybdenum (Mo), which enhance their toughness and resistance to thermal fatigue.

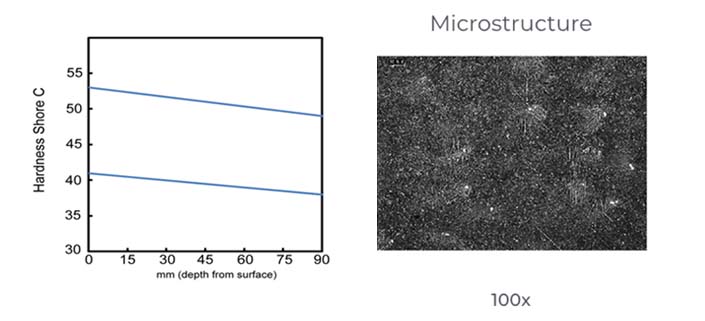

The manufacturing process involves a multi-stage heat treatment—beginning with annealing and followed by carefully controlled tempering cycles. This process imparts outstanding wear resistance, fire crack resistance, and ensures constant hardness across the working layer. Structurally, these rolls feature a fine pearlitic matrix with spheroidized carbides. One of their key advantages is uniform hardness from surface to core, providing stability and durability even under extreme operating conditions. For mills seeking top-tier performance and long-term reliability, Vimco Rolls ranks among the top Alloy Steel Base (Adamite) Rolls manufacturers, trusted for excellence in quality and engineering

Applications

- Roughing stands for TMT Bar, Wire Rod and Hot Strip Mills

- Roughing, Intermediate and Finishing stands for Section and Structural Mills

- Rail Mills, Universal Beam Mills, and Billet Mills.

Grades

- AD-42 (40-45 Shore C)

- AD-47 (45-50 Shore C)

Mechanical Properties

- Tensile Strength: 500-700 Kg/mm²

- Bending Strength: 750-1000 Kg/mm²

| Chemical Composition |

|---|

| Grade | Hardness (Shore C) |

C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

|---|---|---|---|---|---|---|---|---|---|

| AD-42 | 40-45 | 1.4-1.6 | 0.5-0.8 | 0.4-0.7 | 0.05 Max | 0.05 Max | 0.8-1.2 | 0.4-0.8 | 0.2-0.4 |

| AD-47 | 45-50 | 1.6-1.9 | 0.6-1.0 | 0.4-0.7 | 0.05 Max | 0.05 Max | 1.0-1.5 | 0.8-1.2 | 0.2-0.5 |

| AD-52 | 50-55 | 1.6-2.1 | 0.7-1.0 | 0.3-0.7 | 0.05 Max | 0.05 Max | 1.1-1.6 | 1.0-1.5 | 0.2-0.5 |