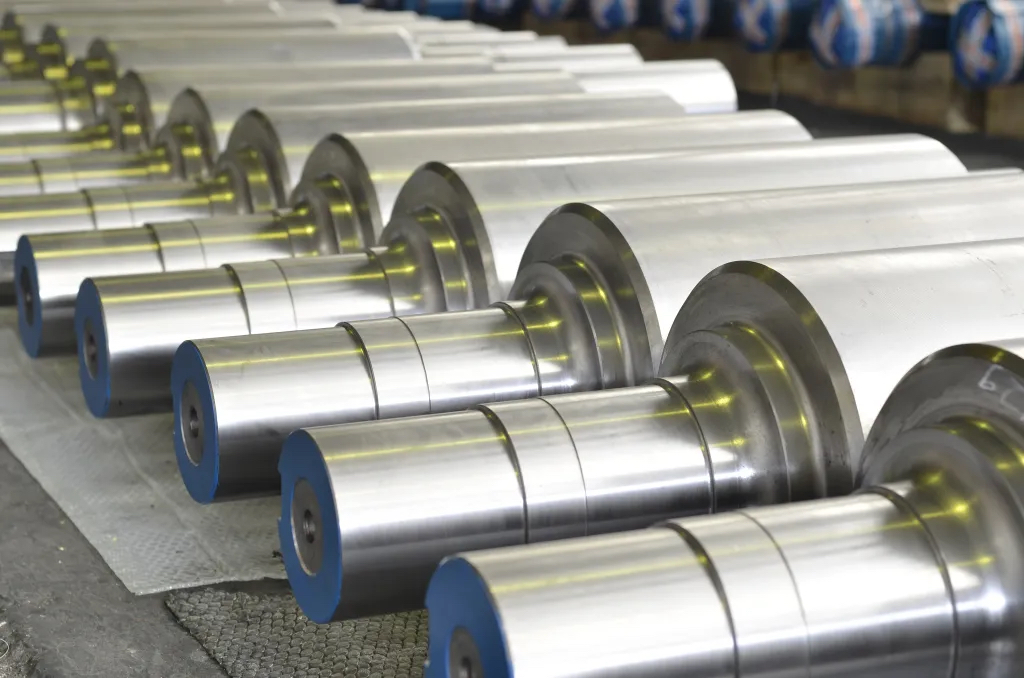

High Speed Steel (HSS) Rolls

High-speed steel rolls generally have a single-groove (time) steel passing capacity that is 3 to 5 times that of high-nickel-chromium rolls. The single groove (times) has a high amount of steel, which saves the time for roll changing, improves the operation rate of the rolling mill, reduces the consumption of rolls, reduces the production cost, and improves the overall benefit of the factory.

The HSS material is rich in alloying elements such as Molybdenum (Mo), Vanadium (V), Tungsten (W), and Chromium (Cr), which contribute to the formation of high-hardened eutectic and secondary carbides like MC, M2C, and M6C. These carbides are evenly distributed within a tempered martensitic matrix, providing outstanding wear resistance, thermal crack resistance, and surface roughness resistance.

During hot strip rolling, the interaction between the steel strip and the roll surface leads to the formation of a thin, adherent oxide film. This film enhances wear resistance and helps maintain the strip's surface quality. These properties make Vimco Rolls a trusted choice for industries seeking reliable and high-performance rolling solutions.

If you're searching for the best HSS rolls manufacturer in India, Vimco Rolls is your go-to partner for precision, performance, and long-lasting results.

Advantages over Conventional Cast Iron Rolls

- Increase in Pass life of Roll:It is estimated that the useful life of HSS rolls is almost 5-6 times more than that of conventional rolls. Meaning that over all cost of rolls consumed per tonne of finished steel produced is much less.

- Increase in Efficiency & Output of Mill:The regular change of roll pass after wearing out consumes a lot of time and results in production loss and huge energy loss. Because of the longer pass life of the HSS rolls the time required for repetitive changing of roll pass is considerably reduced.

- Better Surface finish of Product:Since the passes of the HSS rolls have a greater resistance to wear and tear, the shapes of the grooves are stably maintained. Due to higher wear resistance property compared to conventional rolls, the frictional impact during each pass is minimum which results in better quality of rolled product for a longer tenure.

Applications

- Finishing stands for TMT Bar and Wire Rod Mills

- Slitting and Dog bone stands of Rebar Mills

Grades

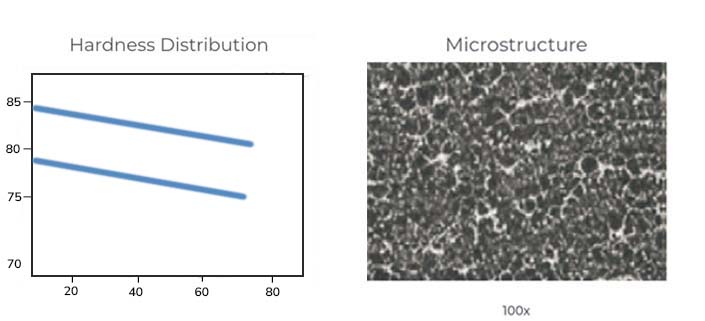

- Semi-HSS (80-85 Shore C)

- HSS (80-85 Shore C)

Mechanical Properties

- Tensile Strength: ≥350 Kg/mm²

| Chemical Composition |

|---|

| Grade | Hardness (Shore C) |

C% | Mn% | Si% | Cr% | Ni% | Mo% | V% | Nb% |

|---|---|---|---|---|---|---|---|---|---|

| Semi-HSS | 80-85 | 0.6-1.2 | 0.5-1.0 | 0.8-1.5 | 3.0-9.0 | 0.2-1.2 | 2.0-5.0 | 0.4-3.0 | 0.1-8.0 |

| HSS | 80-85 | 1.5-2.2 | 0.4-1.2 | 0.3-1.0 | 3.0-8.0 | 0.1-1.5 | 2.0-8.0 | 2.0-9.0 | 0.1-3.0 |