Indefinite Chilled Double Poured (ICDP) Rolls

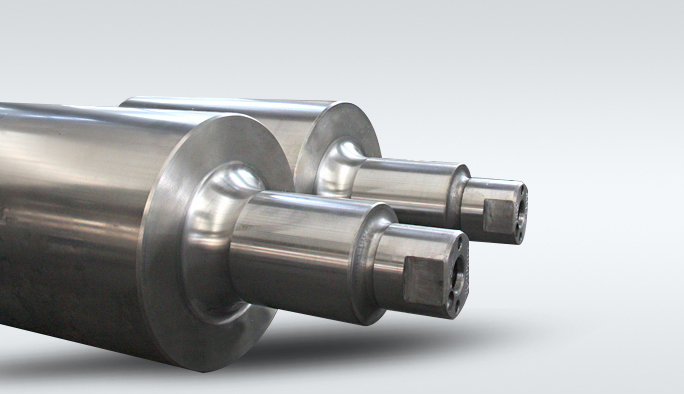

Vimco Rolls Pvt Ltd stands out as the best ICDP rolls manufacturer in India, offering high-performance Indefinite Chilled Double Poured (ICDP) Rolls that meet the demanding needs of modern rolling mills. These rolls feature a hard alloyed iron working layer combined with a softer grey iron or nodular iron core, delivering the perfect balance of durability and strength.

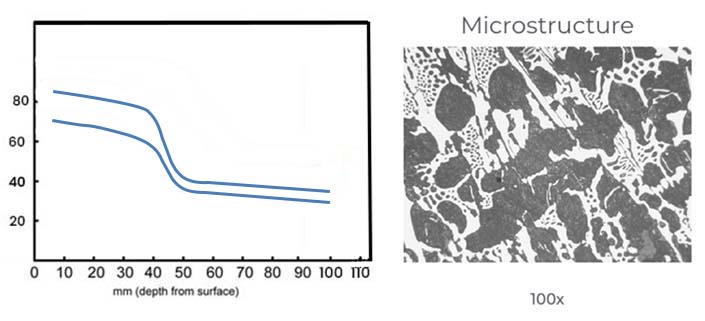

Manufactured using a combination of spin and static casting techniques, ICDP rolls from Vimco Rolls exhibit a bainitic matrix on the surface, with the amount of flaky graphite gradually decreasing toward the center. This unique structure, along with the soft iron core, ensures exceptional mechanical properties, excellent wear resistance, and reliable fracture toughness.

The presence of flake graphite contributes to improved thermal conductivity and enhanced roll life, making these rolls ideal for applications where surface finish quality and roll integrity are critical.

When performance and reliability matter most, trust Vimco Rolls

– the best ICDP rolls manufacturer in India

– to deliver cutting-edge roll solutions engineered for excellence

Applications

- Intermediate/Finishing stand of Wire Rod Mills, TMT Mills and Structural Mills

- Finishing stand of Strip, Sheet and Flat rolling mills.

Grades

- IC-III

- IC-IV

- IC-V

Mechanical Properties

- Tensile Strength: 400-500 N/mm²

- Bending Strength: 700-1000 N/mm²

| Chemical Composition |

|---|

| Grade | C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% | |

|---|---|---|---|---|---|---|---|---|---|

| IC-III | Shell | 3.0-3.6 | 0.4-1.2 | 0.6-1.2 | 0.05 max | 0.050 max | 0.7-1.2 | 2.0-3.0 | 0.2-1.0 |

| IC-IV | Shell | 3.0-3.6 | 0.4-1.2 | 0.6-1.5 | 0.05 max | 0.05 Max | 1.0-2.0 | 3.0-4.0 | 0.2-1.0 |

| IC-V | Shell | 3.0-3.6 | 0.4-1.2 | 0.6-1.5 | 0.05 max | 0.05 Max | 1.0-2.0 | 3.0-4.8 | 0.2-2.0 |

| Core | 3.1-3.5 | 0.6-0.9 | 1.2-1.5 | 0.05 max | 0.05 Max | 0.2-0.5 | 0.4-1.0 |