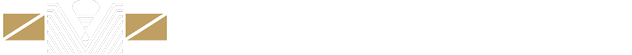

Spheroidal Graphite Iron (Acicular) Rolls

Best Spheroidal Graphite Iron (Acicular) Rolls Manufacturer in India – Vimco Rolls Pvt Ltd

Vimco Rolls Pvt Ltd is recognized as the best Spheroidal Graphite Iron (Acicular) Rolls manufacturer in India, delivering superior quality rolls engineered for strength, durability, and precision performance in a wide range of rolling mill applications.

These Spheroidal Graphite Iron Bainitic Acicular Rolls, commonly referred to as “Acicular Rolls,” are alloyed with a higher percentage of Nickel (Ni) and Molybdenum (Mo), resulting in a robust bainitic matrix enriched with carbides. This unique composition provides significantly enhanced strength, toughness, and wear resistance compared to traditional SGI Pearlitic Roll.The name "Acicular" comes from the distinctive needle-like structure of graphite and carbide within the bainitic matrix. These rolls are known for their high hardness, deep hardness penetration, and consistent performance under demanding conditions.

Acicular rolls from Vimco Rolls are ideally suited for a variety of mills and applications, but it's important to ensure sufficient water cooling during operation to achieve their maximum potential and longevity. When you're looking for the best Spheroidal Graphite Iron (Acicular) Rolls manufacturer in India, Vimco Rolls Pvt Ltd is the name industries trust for innovation, quality, and lasting performance.

Applications

- Intermediate and Finishing Mill stands for TMT Bar Mills, Rail and Structural Mills.

- Intermediate and Finishing Stands of Wire rod and Strip Mills

Grades

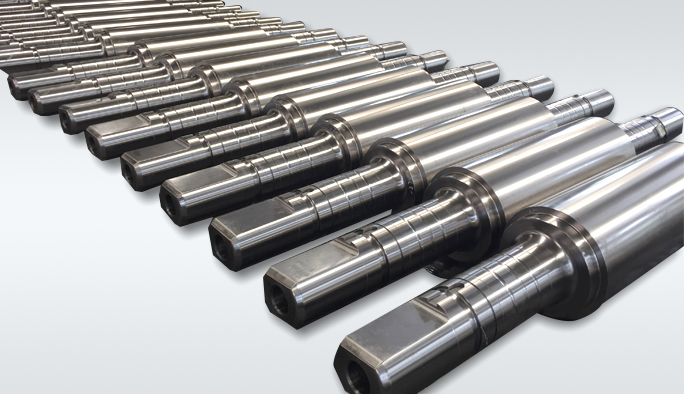

- SGA-62 (60-65 Shore C)

- SGA-67 (65-70 Shore C)

- SGA-72 (70-75 Shore C)

Mechanical Properties

- Tensile Strength: 450-600 Kg/mm²

- Bending Strength: 800-1100 Kg/mm²

| Chemical Composition |

|---|

| Grade | Hardness (Shore C) |

C% | Mn% | Si% | S% | P% | Cr% | Ni% | Mo% |

|---|---|---|---|---|---|---|---|---|---|

| SGA-62 | 60-65 | 3.0-3.4 | 0.4-0.7 | 1.3-1.6 | 0.02 Max | 0.05 Max | 0.4-0.7 | 2.0-2.5 | 0.4-0.7 |

| SGA-67 | 65-70 | 3.1-3.5 | 04-0.7 | 1.2-1.5 | 0.02 Max | 0.05 Max | 0.4-0.8 | 2.5-3.0 | 0.6-0.9 |

| SGA-72 | 70-75 | 3.2-3.6 | 0.4-0.7 | 1.2-1.5 | 0.02 Max | 0.05 Max | 0.4-0.8 | 2.8-3.4 | 0.8-1.0 |